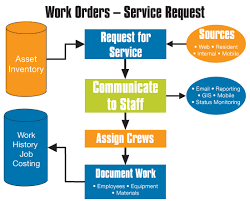

Implementing a Computerized Maintenance Management System (CMMS) can be an overwhelming task. We will cover implementation in upcoming blogs (stay tuned!). For now, let’s tackle the topic most people start with – work orders.

The first step is to settle on a process for managing work orders. When consulting with new clients, we like to start by looking at their existing process. It doesn’t matter if it’s electronic or paper, there are reasons for the process and we try not to disrupt that process in a way that makes it onerous for everyone.

Here are our top 10 work orders questions to ask:

- Who submits work orders?

- Who approves them before they are viewed by maintenance?

- Who, within maintenance, approves the work orders?

- Who assigns the them?

- Who prints the them?

- How are they distributed?

- What data is collected by the tradesmen/field techs?

- How are the work orders returned by tradesmen/field techs?

- How are the returned work orders reviewed?

- Who enters/files the tradesmen completed work order data?

Once these process steps are established, you will need to review each step. Ask yourself “why do we do this”? If the answer is “because we’ve always done it that way” then seriously consider what, if any, value there is in that step. If there is no value, alter or eliminate the step. If there is value, see where that step belongs in your new CMMS process.

Once you’ve reviewed and narrowed down the steps, you will need to consider how to transition from your current process. For example, currently the administrator of the building submits a paper work order via courier mail. We are replacing that step with an internet work order request form with the same data. Or maybe the field techs come in every day to pick up their work orders for the day and now you can notify them via email or text on their device, eliminating the screen time driving to the office.

You simply need to replace each step of the old system with each step of the new system and account for the changes you determined necessary earlier in this process.

There is a reason why you have your current processes in place. It is probably a good, tried and true process, and maybe doesn’t maintain the data you need for capital planning or KPI’s. Use what you have to build your new process and then simply migrate the new technology into the existing process.